Product Consultation

Your email address will not be published. Required fields are marked *

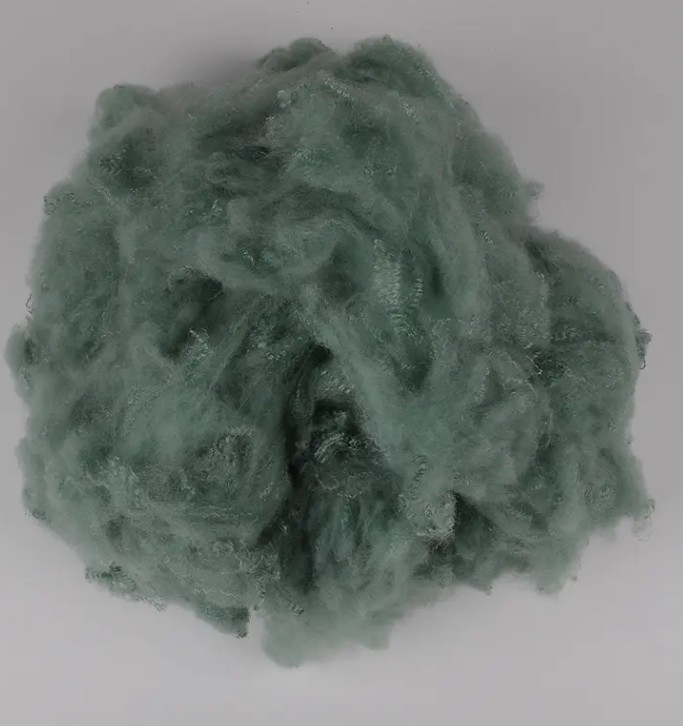

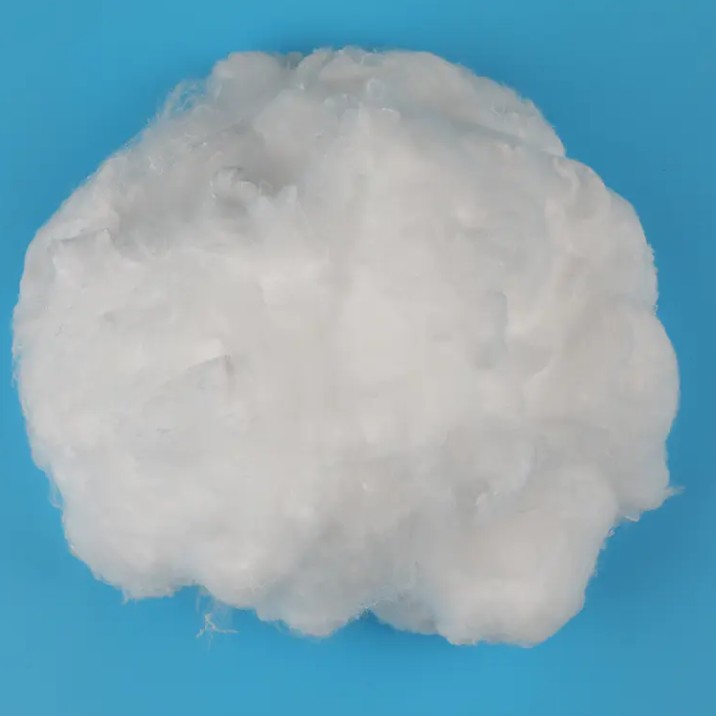

In the field of textile and industrial materials, PE/PP bicomponent fiber, as a new type of composite material, is gradually emerging with its unique performance advantages and becoming an important force to promote the development of the industry.

PE/PP bicomponent fiber is made by blending and spinning two polymer materials, polyethylene (PE) and polypropylene (PP), through a special process. This composite material not only inherits the flexibility and chemical corrosion resistance of PE, but also combines the high strength and high temperature resistance of PP, thus showing a better overall performance. Specifically, PE/PP bicomponent fiber has the characteristics of softness and comfort, wrinkle resistance and anti-static, wear resistance, chemical corrosion resistance and good heat resistance. These characteristics enable the material to maintain stable performance in a variety of complex environments, providing a more reliable choice for textile, industry and other fields.

The production process of PE/PP bicomponent fiber combines advanced spinning technology and precision processing technology. After PE and PP are mixed in a certain proportion, they are melted at high temperature to form a uniform melt. Subsequently, the melt stream is stretched at a certain speed through a special spinning machine to become thinner and longer, and then cooled and solidified in the air to form a composite fiber with a skin-core structure. In this process, parameters such as temperature control, stretching speed and cooling conditions have an important impact on the final performance of the fiber. Therefore, every detail in the production process needs to be strictly controlled to ensure the stability and consistency of fiber quality.

PE/PP bicomponent fiber has shown broad application prospects in many fields due to its performance. In the textile field, this material can be used to make high-performance sportswear, outdoor clothing and home textiles, etc. Its soft and comfortable feel and wear resistance are deeply loved by consumers. At the same time, PE/PP bicomponent fiber also has good air permeability and antibacterial properties, which makes it occupy a place in the production of medical and sanitary materials such as masks, bandages and other products. In the automotive industry, this material is also widely used in the manufacture of interior parts, seats and other components, and its light weight, high strength and wear resistance improve the overall performance and comfort of the car.

With the continuous development of the global economy and the improvement of people's living standards, the demand for high-performance and environmentally friendly materials is growing. PE/PP bicomponent fiber is gradually becoming the new favorite of the market with its unique performance advantages and wide application fields. Especially driven by the rapid growth of the non-woven materials market, the demand for PE/PP bicomponent fiber has shown an explosive growth trend. According to market research institutions, the global bicomponent fiber market will continue to expand in the next few years, of which PE/PP bicomponent fiber will occupy an important share.

As a new type of composite material, PE/PP bicomponent fiber is gradually changing the pattern of textile and industrial materials with its performance and wide application prospects. With the continuous advancement of science and technology and the increasing demand for high-performance materials, the market potential of PE/PP bicomponent fiber will be further released. In the future development, PE/PP bicomponent fiber will continue to play its unique advantages, bring more innovations and breakthroughs to the textile and industrial fields, and lead the industry to develop in a more environmentally friendly, efficient and sustainable direction.

Technological innovation and differentiated development of PSF (polyester staple fiber)

2024-09-08

PE/PET bicomponent fiber: innovative fiber materials lead the new trend of the industry

2024-09-22Your email address will not be published. Required fields are marked *

Focusing to the research and production of differentiated fiber. Applying recycle-material processing scientifically.

Zhulinjizhen, Xinfeng Town, Jiaxing City, Zhejiang Province

Copyright @ 2023 Jiaxing Fuda Chemical Fiber Factory All rights reserved

Polyester Staple Fiber Manufacturers

Friendship link - Anhui Fulin Environmental Protection Technology Co., Ltd.:https://www.ahflhb.com